Guide Wheel Liners for Mine Hoists: Supporting Heavy Load Handling with Precision

Mines need to manage and transport a great deal of hefty loads every time. Mine hoists are an part is integral of process. Hoists lift and move loads being heavy mines. These lots can be rock, ore, or even gear. One component is vital plays an important roles in hoist operations is the guide wheel liner. This short articles covers guide wheel liners for mine hoists and how they are critical for the efficiency and security regarding the hoist operations

Advantages of Guide Wheel Liners

Guide wheel liners offers a few advantages that boost the performances of mine hoists. One of the many advantages being significant that it reduces vibration and noise during hoist operations. This makes the hoist more quiet and efficient, reducing the probability of accidents. Additionally, guide wheel liners improves the hoist's overall security, ensuring that Steel Wire Rope heavy loads move seamlessly without the instability or wobbling

Innovation in Guide Wheel Liners

Guide wheel liners have improved over time. The manufacturers now use high-quality materials, contemporary technology, and design is revolutionary. This ensures they can withstand the harsh conditions of mines while at enough time is same the strict safety criteria during hoist operations

Safety of Guide Wheel Liners

Safety is paramount in mines, and the employment of guides wheel Friction liner improves safety during hoist operations. The risk is paid down by the liners of accidents by ensuring that loads move smoothly plus don't cause any instability. Also, they functions as surprise absorbers, reducing the effect for the load during sudden movements

Use of Guide Wheel Liners

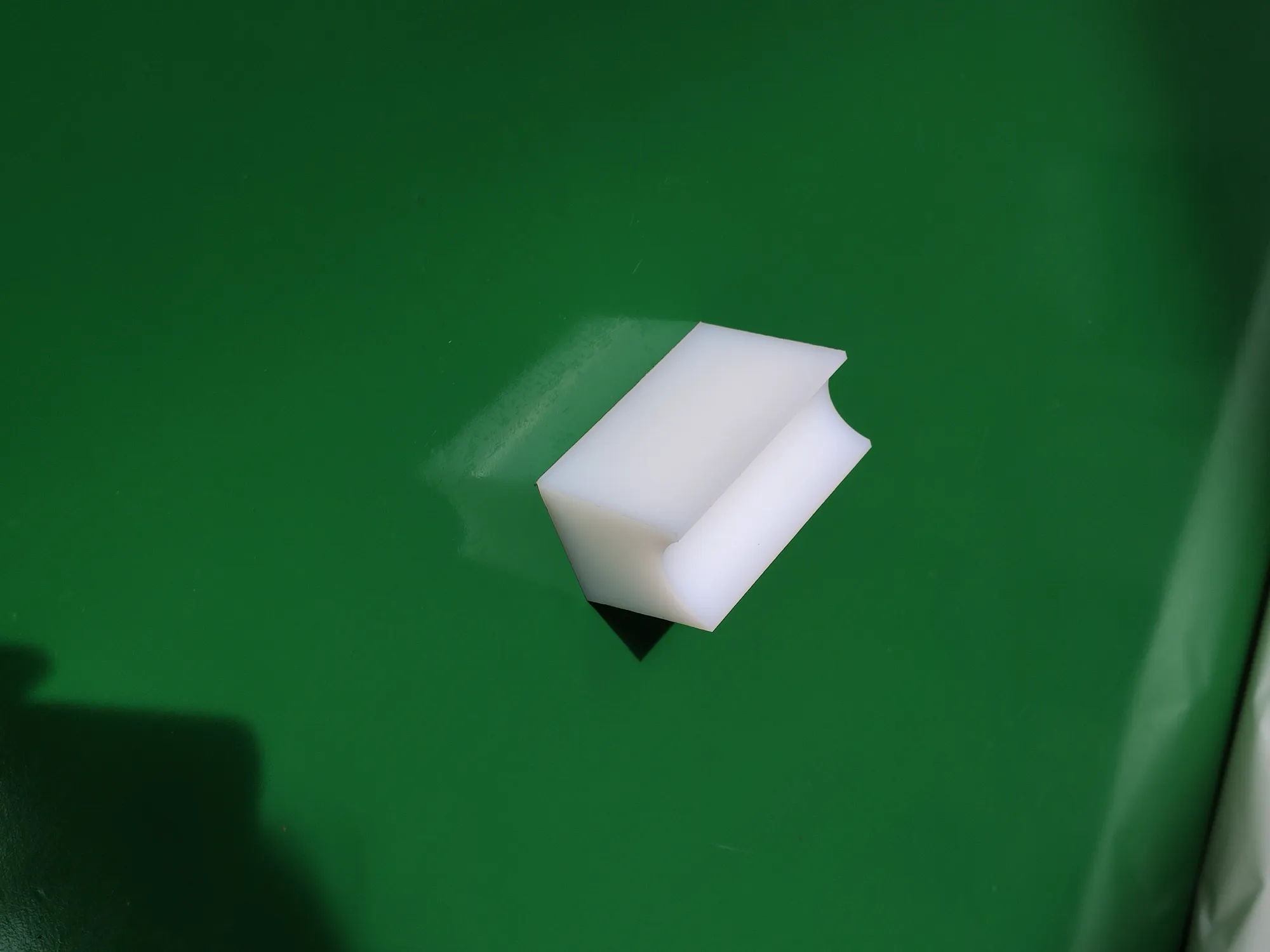

Guide wheel liners are vital components of mine hoists. They become supports systems with the responsibility of guiding lots that are heavy. The liners are situated in the wheel that supports the CNC lathe rope groove device hoist cable. They provide a surface is smooth the cables to glide on as it moves down and up the hoist system

How to Use Guide Wheel Liners

Making use of guide wheel liners is easy. They come in different sizes and shapes to fit hoist is different. The user has to ensures it following the manufacturer's instructions they've the right liner for their hoist and install. Regular maintenance is also essential to ensures that the liners remain in top conditions and continue steadily to offer the help that's needed is

Service and Quality of Guide Wheel Liners

The products quality of guide wheel liners is vital to ensures that the support is offered by them needed during hoist operations. Manufacturers use high-quality materials, such as nylon, polyurethane, or rubber, to make sure which they can handle the conditions that are tough mines. Regular maintenance is a must to make sure that the liners stay in top condition. In situation of any damages, users need to immediately replace the liners to avoid any accidents during hoist operations

Application of Guide Wheel Liners

Guide wheel liners have various applications in mine hoists. They offer supports for the hoist cable, supply a surface is smooth the cable to glide on, and reduce the danger of accidents. Guide wheel liners are very important in mine hoists that handle heavy loads, including rock, ore, and equipment

Guide wheel liners are critical components of mines. They feature several advantages, including paid off vibrations and noise, increased stability, improved security, and accidents that are minimized. Manufacturers of guides wheel liners utilize innovative designs and materials that are high-quality CNC lathe rope groove device ensures that they withstand the harsh conditions in mines. Regular maintenance is also crucial to make certain that these liners remain in top conditions and gives the supports needed during hoist operations. Guide wheel liners are essential components of mines and play a job is vital ensuring the safety and efficiency of hoists operations.

Comments

Post a Comment